The steadily high growth of international and domestic shipping volumes, that has continued in recent years, strengthens the competitive environment and price policy in stevedore companies’ business and requires terminals’ logistics structures optimization.

With e volume of sea freight traffic and capacity of vessels increased, less time is allotted for transshipment operations, and the number of port calls that need to be processed constantly grows.

As a result, there is a growing demand for radical innovative technological solutions and more advanced and reliable equipment for fast, safe and efficient transshipment of goods.

The technical equipment of the ports includes, for example, automatic mobile gantry cranes for transshipment of containers, which are an intermediate link between loading and unloading devices and storage areas located directly near water and on land, as well as with rail and road transport. Also, the scales installed at the entrance to the terminal, or quality assessing laboratory of imported grain, can be included in the same category. As a rule, seaports are oriented primarily towards such technical equipment in order to mitigate the tension in the transshipment of increased volumes of cargo and to be able to handle ever larger vessels in the shortest possible time at the port.

Such systems may have a number of purposes, like :

- Ensuring stable and efficient operation of the terminal, labor organization, resource management, monitoring and analysis of production indicators

- Automation of cargo operations management and providing accurate information about the current situation at the terminal

- Organization of operational work with customers, third-party carriers and customs authorities through automatic data exchange

- Improving efficiency and reliability of the information on the state of the transportation process, improving the quality of planning and management;

- Minimization of unproductive downtime of wagons, cars, marine vessels in the part depending on the terminal

- The exception of manual data entry, the recording of events using data already in the system, the exception of the manual maintenance of established forms of accounting and reporting

Today, the highest level of automation is typical to large container terminals: almost all of them have WMS (warehouse management system), TOS (terminal operating system) or OCR (optical character recognition) for recognizing container and vehicle numbers. Things are much worse with general cargo terminals that handle general cargo, and with specialized terminals, such as, for example, coal terminal.

At bulk terminals, there is no need to control elevators, mechanical and other loading equipment. As well, you don’t need any automation of equipment at liquid bulk terminals, since all necessary automated systems are already supplied with the equipment, so there is no need in additional automation. The main problem of such terminals is document flow with counterparties, which is mainly on paper.

As the information systems of any terminal develop, they need to interact with external participants in the transshipment process. For example, it can be both terminal customers and government agencies, for example, customs and border services.

Information systems for terminals are divided into several classes depending on the purpose and complexity. The most complex is TOS (Terminal Operating System), designed to control personnel and equipment at the terminal in real-time and aimed at improving the efficiency of cargo handling. Less complex is WMS (Warehouse Management System) usually use to plan to position at warehouses and to control the deadline of some goods. Another class of automation systems — document workflow systems — is used to register and record documents at the terminal and covers the entire workflow of the terminal with the exception of accounting. In addition, specialized automation systems are being introduced at container terminals: security systems, number recognition systems for containers, cars and railway platforms, etc.

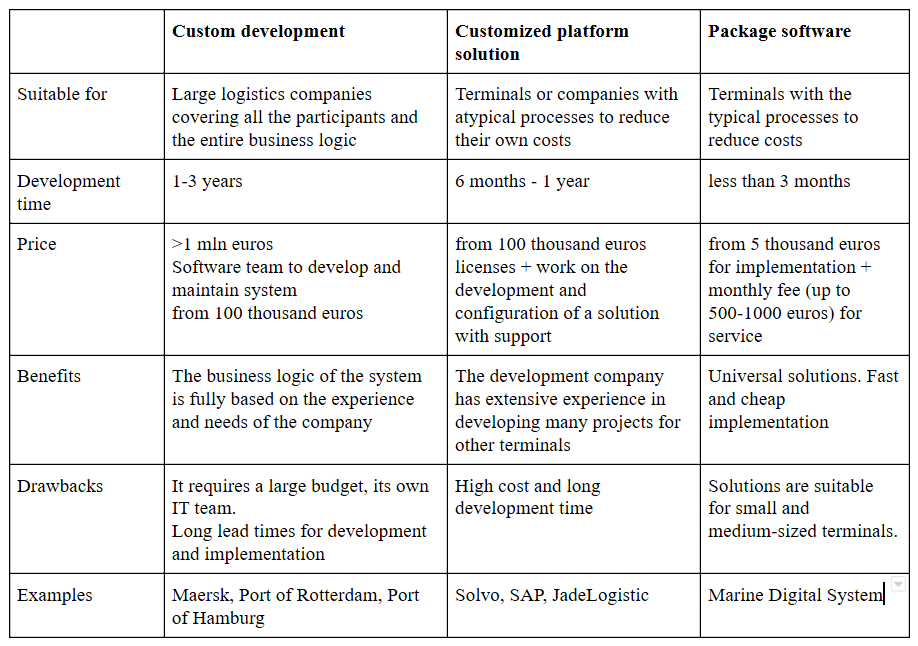

There are various approaches to the process of automation and implementation of terminal information systems:

A terminal that decides to modernize its business processes by implementing information systems should, first of all, understand why this modernization is necessary and choose an approach based on relevant expectations and capabilities. A large terminal is suitable for industrial solutions and development for its own requirements in order to optimize processes, increase management efficiency and maintain its own expertise within the company. To quickly solve problems with implemented automation, it is normal to take ready-made solutions and integrate them into the existing IT infrastructure of a large terminal. For small and medium-sized terminals, with a limited budget, the functionality of off-the-shell products would be enough to solve operational problems. At the same time, there is always the opportunity to refine such decisions for yourself. The main thing is that the technology of such a solution allows it to be implemented on its own or with the involvement of third-party specialists at a reasonable cost.

The Marine Digital System platform implements this opportunity because written on popular technologies, it implements ready-made WMS(Warehouse management system), QMS (Queue Management System) and other modules within the framework of TOS (Terminal Operating System), which are easily integrated with each other and can be improved.

Source: medium.com