TOP 5 factors contributing to lower fuel costs for Shipping companies

Get a presentation with a full description of the features and free pilot project with trial of Marine Digital FOS for 2 months

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy"

Get an overview "The Pathway to Zero Carbon Shipping:

IMO Compliance and CII Optimization through SEEMP" on email and download it for FREE! Leave your email now!

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy, as well as consent to subscribe to the newsletter. "

Ship Energy Efficiency Management Plan (SEEMP)

Fleet Managers need to measure and control GHG emissions from the already existing shipping fleet. IMO has developed and structured a special tool called the Ship Energy Efficiency Management Plan (SEEMP)

Leave your phone for a free demo

Marine Digital provides a solution that converts SEEMP from a possible perception of additional reporting burden to an effective way of monitoring and improving your fleet operation efficiency bringing cost and emission reduction.Marine Digital SEEMP solution is structured into 3 layers making easy and fast roll out for all the ships across your fleet:

Marine Digital SEEMP part I: factor analysis. It's purely operation efficiency analytical and decision support configuration. It can be populated across a selected fleet within a day. Technology behind is based on historical vessel tracks, weather data and ship physical models so called "digital twins". There is a complicated statistical, ML and physical modeling behind the output.

Marine Digital SEEMP part I: factor analysis. It's purely operation efficiency analytical and decision support configuration. It can be populated across a selected fleet within a day. Technology behind is based on historical vessel tracks, weather data and ship physical models so called "digital twins". There is a complicated statistical, ML and physical modeling behind the output.

It's not designed for a regulated reporting needs but clearly gives indicative fleet efficiency factor indication for a voyage speed\shaft power and Just in time arrival. There are both fleet consolidated summary and a detailed report for each voyage from the past two years providing:

- potential efficiency gain from maintaining constant STW profile;

- potential efficiency gain from maintaining Just in time arrival eliminating anchorage waiting time to enter a port;

- ship, port and voyage benchmarking identifying most critical elements of the fleet structure and logistical chain.

Get free test access with a description of the solution

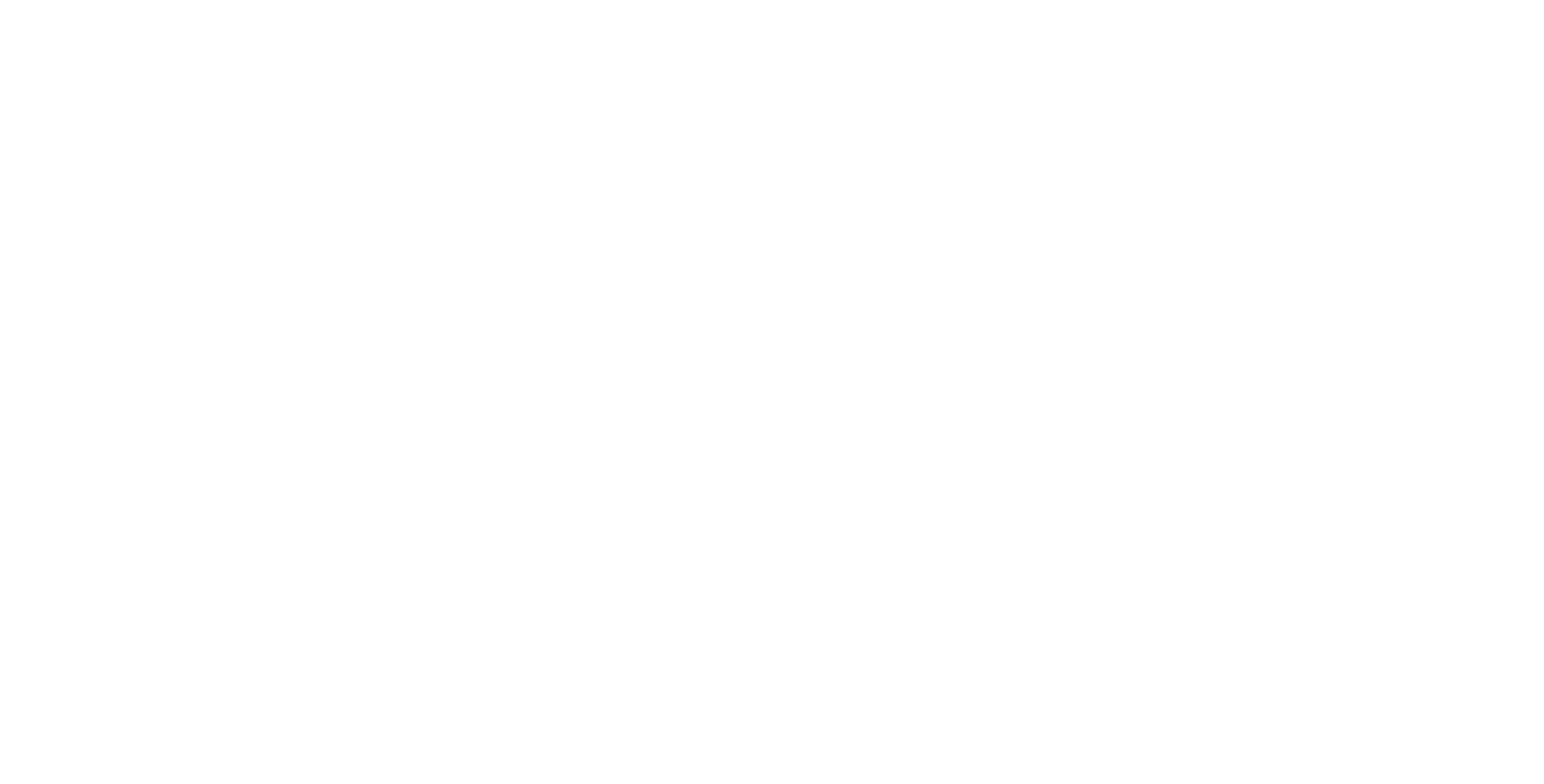

Marine Digital SEEMP part II: reporting automation. This is a next product layer that includes digital on-board "noon-reporting" solution addressing requirements of MARPOL Annex VI and related Administrations for a fuel data consumption quality. Marine Digital application for reporting is configurable to reflect specifics of a particular ship design and includes automated prefilling and validity check of the reported data.

This makes reporting less time consuming for the crew and eliminates probability of a human factor related errors. Personnel in the office can access the reported data in real time through a web dashboard, validate it and get automated derivative reports required by the regulations:

Digital noon reporting solution could be delivering data to the office by email, automated pre filling and validity check would require internet connection with a minimum bandwidth.

- bunker delivery notes summaries (MEPC 71/17/Add.1, Annex 16, APPENDIX 1)

- ship collected data summaries (MEPC 71/17/Add.1, Annex 16, APPENDIX 2)

- ship fuel oil consumption data collection plan (MEPC 70/18/Add.1,Annex 10, APPENDIX 2)

- ship collected data report (MEPC 70/18/Add.1,Annex 10, APPENDIX 3).

Digital noon reporting solution could be delivering data to the office by email, automated pre filling and validity check would require internet connection with a minimum bandwidth.

Get free test access with a description of the solution

Marine Digital SEEMP part III: Advanced factors. Marine Digital most advanced solution based on sensor data collection from on-board a ship. It's almost a complete automation of noon reporting data collection where up to 80% of parameters are prefilled from the sensor measurements and a crew member just validates them before submission. It remarkably increases reliability of the data and decision making. Besides that, the machine learning system is building a precise digital twin model of the ship's performance and actual fuel consumption curve. This brings the product up to a level of insight for hull and propeller degradation effect in terms of fouling and damage. A fleet manager could monitor and evaluate the impact making decision on continuation of operations or ship docking based on transparent cost scenarios.

Our solution is designed in a way to minimize cost and roll-out time impact as much as possible. It's based on non-invasive sensors, wireless connectivity and dedicated on-board computational units. It's avoiding connectivity to business-critical networks to maintain cybersecurity and simplify any on-board approval requirements. Dedicated computational unit eliminates dependency from an internet connectivity loss as well as brings down requirements to the connectivity bandwidth.

Leave your email to get a FREE overview of how Digital Noon Report helps to generate the data required for IMO reporting. Moreover, you will get FREE access to the Marine Digital voyage optimization system for 1 month by signing LOI + NDA!

Аdvantage of Marine Digital FOS:

Marine Digital FOS can be integrated with other system and third-party's solutions through the API. To implement vessel performance monitoring for any vessel, we are using mathematical algorithms, machine learning and the same equipment as in FOS. The more data we collect from vessels, the more precise reports and recommendations our system will perform according to your individual requirements in fleet management.

If you have any questions about the solutions and the Marine Digital platform, write to us, we will be happy to answer.

If you have any questions about the solutions and the Marine Digital platform, write to us, we will be happy to answer.

Increased business process speed

Reducing to zero the number of errors

Best offer to the clients

Reduction in operating expenses

Have a questions?