After 10 years in logistics, finance and IT sector, we moved to Europe for launching our startup in maritime logistics.

In Russia, there’s one authority that decides on automation issues in ports and terminals — Rosmorport, and it may take years to have new technologies approved and implemented.

Generally speaking, there is no market for a maritime logistics startup in Russian.

We have traveled with representatives of ports, terminals, shipping companies, freight forwarders and agents to Lithuania, Latvia, Finland, and the Netherlands, where we saw the real work with goods and the need for terminals to solve the problems of accounting and planning of cargo turnover.

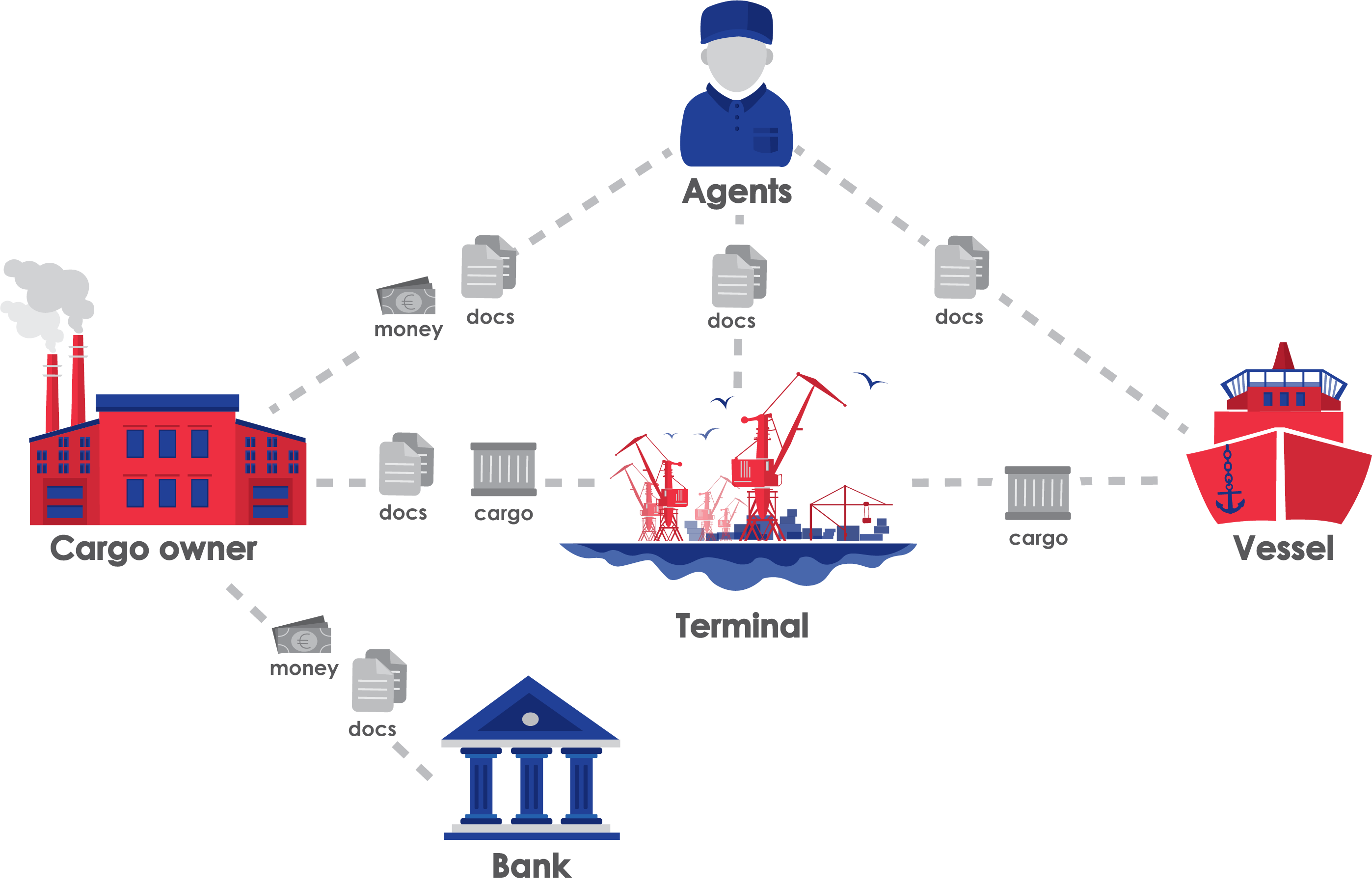

The terminal is one of the elements in the supply chain. All the elements in such a chain should effectively interact with each other to increase turnover and the amount of profit, but the warehouse terminal has the most difficult because It is a multiply link in the supply chain.

The problems that arise at the terminal directly affect all participants in the supply chain, which, in essence, is a set of interconnected processes. The greater the cargo turnover and the number of parties, the more difficult it is to manage the process of receiving and sending goods at the terminal. The most difficult thing at terminals is working with bulk and general cargo, where there are regular problems:

Unloading and loading vehicles

The long passage of the checkpoint by trucks, the parking of trucks, wagons and a vessel carry direct costs and lost profits of the terminal and the shipper, and non-optimal routes along the territory of the terminal entail unnecessary expenses for fuel and loss of time.

Weight control

It is clear that at the terminals working with all goods, there are factors affecting the weight, for example, natural decrease or humidity. But the main problems arise due to the human factor: errors in double counting and workflow. The costs for the operator of the scales are constant, while his work has a periodic load.

Accounting and distribution of freight lots at the warehouse

Keeping a manual record on paper and in Excel does not give a complete picture of the location of the cargo and the optimal formation of cargo lots. It takes a lot of time to search for information and its verification. There is a dependence on individual employees and the need to expand the staff when processing a larger number of applications, which may depend on the season.

Document mismatch

At all stages of work with cargo at a terminal, it is required to verify documents and enter data into the accounting system. Errors occur even when generating documents of the same type, and a large amount of time is spent searching for documents based on shipments made.

This processes reduce the speed of cargo turnover, makes the operational planning and management of activities at the cargo terminal nearly impossible, increases costs and affects the loyalty of customers (cargo owners) who are interested not only in the low cost of terminal services, but in reducing their costs associated with supply, production, storage and delivery of products. For cargo owners the effectiveness of the information flow and the exchange of information between all participants in the supply chain is very important, sometimes this leads to a reduction in downtime, delays and associated costs.

Automation of a terminal will significantly accelerate processes, optimize the movement of material flows and distribute the load without increasing the number of personnel.

We have developed TOS (Terminal Operating System) for small terminals that do not have a budget for implementing the platform solutions and have to use Excel, enter data from paper documents into various accounting and reporting forms manually.

Our TOS is called Marine Digital System. It automates the entire process from planning the arrival of goods in transport and electronic queue to accounting and distribution of cargo with all documents. The system is already being piloted at 4 sea terminals and has shown in practice that its use gives the terminal a competitive advantage and attracts more customers and orders by increasing loyalty and quality of service. It reduces the lead time, makes it possible to establish guarantees on time and sets more attractive prices while maintaining margin!

How does the Marine Digital System work?

The Marine Digital System includes solutions for automating the entire process from planning the arrival of goods in transport and the electronic queue to accounting and distribution of cargo with all documents and the formation of an electronic bill of lading:

QMS — Transport electronic queue management

WMS — Warehouse Management with Visual Module

Weight module

PMIS — Port Call Management

Trade Finance module for electronic document management and data exchange with the bank

The key difference of the Marine Digital System is its modularity and cloud format, where the total cost of ownership of a customized solution does not exceed 490 € per month. Separate solutions, for example, Weight module and Electronic queue, cost from 90 € per month. The SaaS model ensures the availability and security of data without the hidden cost of installing hardware, software, and support.

You can get free access to the system for 1 month and advice on setting up the system to your requirements, for this leave a request on the Marine Digital System website

Source: medium.com