How has vessel propulsion changed?

Since the first ships appeared, people want to make them faster and more efficient. For this, the modes of transportation have changed over the centuries. Let's take a look at how ships' engines and propulsion systems have evolved over the years and what the future holds for them.

From the very beginning of human existence, ships were considered as an indispensable means of transportation, trade and war. Mankind does not know what was the first means for overcoming water spaces in humans. There are no chronicles that would record what the very first ship in the world was like, where and by whom it was built: there are only rock paintings. But nevertheless, the ancient Egyptians and their boats, made of reed and papyrus, are considered to be the first: after all, trees in Egypt were rare, very dearly valued, therefore, the first ship in the world was reed. Since then, people have tried to make ships faster and more efficient. For this, the methods of movement have changed over the centuries. From wind and steam to diesel engines and autonomous ships, engines are looking for an innovation, while recently the need for environmentally friendly transportation has become a driving force behind new methods of propulsion and the exploration of potentially new ones. In this article, we would like to look at how engines and propulsion systems on ships have evolved over the years and what the future holds for them.

Before the use of the coal steam engines on ships in the early 19th century, oars or wind were mainly used to propel ships. At that time, merchant ships used sail as well as rowing, which was preferable as it provided maneuverability and speed.

Until the moment when the engines appeared, the sail was not used by the ship as a means of transportation. Recently, however, more and more developments have been taking place in which wind power is used to power ships.

Until the moment when the engines appeared, the sail was not used by the ship as a means of transportation. Recently, however, more and more developments have been taking place in which wind power is used to power ships.

Wind

The first known device, powered by steam, was described by Heron of Alexandria in the first century. Steam escaping tangentially from the nozzles attached to the ball made the latter rotate.

The real steam turbine was invented much later, in medieval Egypt, by the 16th century Turkish astronomer, physicist and engineer Takiyuddin al-Shami. He proposed a method of rotating the spit by means of a stream of steam directed to the blades fixed along the rim of the wheel.

In the 1700s, steam was one of the main sources of energy that propelled ships.

In 1769, the French inventor Nicolas-Joseph Cugnot demonstrated the first operational self-propelled steam vehicle: the "fardier à vapeur" (steam cart). Perhaps his invention can be considered the first car. The self-propelled steam tractor turned out to be very useful as a mobile source of mechanical energy that set in motion other agricultural machines: threshers, presses, etc. In 1788, a steamboat built by John Fitch already carried out regular communication on the Delaware River between Philadelphia (Pennsylvania) and Burlington (New York State). He lifted 30 passengers on board and walked at a speed of 7-8 knots. On February 21, 1804, the first self-propelled railway steam locomotive, built by Richard Trevithick, was on display at the Penidarren Steel Works in Merthyr Tydfil, South Wales.

In fact, there was a large influx of steam ships in 1769, as the steam engine underwent great changes during this time.

During this period, steam powered two types of engines: reciprocating (with steam pistons connected to the crankshaft) and turbines.

The real steam turbine was invented much later, in medieval Egypt, by the 16th century Turkish astronomer, physicist and engineer Takiyuddin al-Shami. He proposed a method of rotating the spit by means of a stream of steam directed to the blades fixed along the rim of the wheel.

In the 1700s, steam was one of the main sources of energy that propelled ships.

In 1769, the French inventor Nicolas-Joseph Cugnot demonstrated the first operational self-propelled steam vehicle: the "fardier à vapeur" (steam cart). Perhaps his invention can be considered the first car. The self-propelled steam tractor turned out to be very useful as a mobile source of mechanical energy that set in motion other agricultural machines: threshers, presses, etc. In 1788, a steamboat built by John Fitch already carried out regular communication on the Delaware River between Philadelphia (Pennsylvania) and Burlington (New York State). He lifted 30 passengers on board and walked at a speed of 7-8 knots. On February 21, 1804, the first self-propelled railway steam locomotive, built by Richard Trevithick, was on display at the Penidarren Steel Works in Merthyr Tydfil, South Wales.

In fact, there was a large influx of steam ships in 1769, as the steam engine underwent great changes during this time.

During this period, steam powered two types of engines: reciprocating (with steam pistons connected to the crankshaft) and turbines.

Steam

The first steamers operated on wood and used aft or side paddle wheels, which later gave way to propeller wheels. The next generation of steamboats used coal or fuel oil, and the first commercial success was achieved on Robert Fulton's North River Steamboat in the United States in 1807.

Reciprocating

Initially, steam turbines were fired with coal, and then with fuel oil, while the ship's steam turbine increased the power density. This allowed the creation of new high-speed liners in the first half of the 20th century, making the reciprocating steam engine obsolete.

Turbines

In the second half of the 20th century, rising fuel costs led to the demise of the steam turbine. In fact, since 1960, most of the new ships were built with diesel engines, which was a revolution. In fact, most modern ships use a piston diesel engine as their prime mover due to their ease of operation, reliability, and fuel economy compared to most other prime mover mechanisms.

Mechanized power

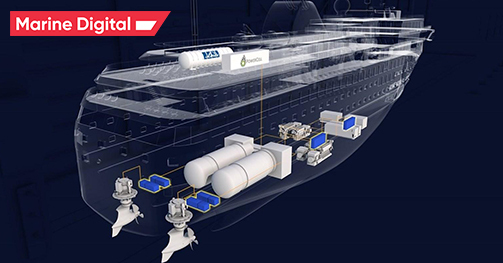

Shipping companies are currently required to comply with IMO decarbonization regulations. To achieve compliance, many operators choose to use alternative fuels as their engine. One of these fuels is LNG.

Alternative fuel engines

The first LNG vessel dates back to 1959, when Methane Pioneer shipped cargo from Louisiana to the UK.

Today, an LNG marine engine can have multiple fuel options, allowing ships to navigate without relying on a single fuel.

In fact, research has shown that LNG can be an efficient transition fuel. However, limited access to LNG filling stations could affect the production of such engines.

Moreover, ships providing services to the LNG industry have been upgraded with dual-fuel engines, with positive results.

Today, an LNG marine engine can have multiple fuel options, allowing ships to navigate without relying on a single fuel.

In fact, research has shown that LNG can be an efficient transition fuel. However, limited access to LNG filling stations could affect the production of such engines.

Moreover, ships providing services to the LNG industry have been upgraded with dual-fuel engines, with positive results.

LNG

To date, no ammonia-fueled vessels have been built, but that has not stopped companies including Maersk, MAN Energy Solutions, NYK Line, Mitsubishi Heavy Industries and the French energy company Total from a rushed effort to bring vessels powered by ammonia fuel.

Ammonia

Another potential fuel that shipping companies are considering is hydrogen. In fact, more and more companies are creating projects to promote the use of hydrogen, such as the Hyundai Heavy Industries Group, which aims to complete the hydrogen value chain from production to transportation, storage and sale of fuel cells by 2030.

Hydrogen

Despite the fact that electric vessels are not the types of propulsion in particular we would like to tell you more about them. First used around the 1880s, today several short-range vessels have been built or converted into electric vessels. This includes battery power that is charged from shore while others are powered from shore using electrical cables.

Specifically, on November 12, 2017, Guangzhou Shipyard International (GSI) launched what is arguably the world's first battery-powered, all-electric land-based coal transporter. The vessel with a deadweight of 2,000 tons will carry bulk cargo up to 40 nautical miles on a single charge. The ship is powered by 2,400 kilowatt-hours of lithium-ion batteries, about the same as the 30 Tesla Model S electric sedans.

Stena Line announced that it plans to order its first all-electric ferry no later than 2025. The Stena Elektra project, a concept for an all-electric ferry on the Gothenburg-Frederikshavn route by 2030, is currently under construction on a commercial vessel. The project was developed by Stena's in-house technical consultant, Stena Teknik.

The company expects to complete the design specifications within a year. While battery ferries are nothing new, the Stena Elektra will be the first major marine ferry to run exclusively on fossil-free energy. Vessels with a length of 200 meters will carry both passengers and trucks in a flexible configuration.

Specifically, on November 12, 2017, Guangzhou Shipyard International (GSI) launched what is arguably the world's first battery-powered, all-electric land-based coal transporter. The vessel with a deadweight of 2,000 tons will carry bulk cargo up to 40 nautical miles on a single charge. The ship is powered by 2,400 kilowatt-hours of lithium-ion batteries, about the same as the 30 Tesla Model S electric sedans.

Stena Line announced that it plans to order its first all-electric ferry no later than 2025. The Stena Elektra project, a concept for an all-electric ferry on the Gothenburg-Frederikshavn route by 2030, is currently under construction on a commercial vessel. The project was developed by Stena's in-house technical consultant, Stena Teknik.

The company expects to complete the design specifications within a year. While battery ferries are nothing new, the Stena Elektra will be the first major marine ferry to run exclusively on fossil-free energy. Vessels with a length of 200 meters will carry both passengers and trucks in a flexible configuration.

Electric vessels

Innovative propulsion technologies that we described in this article also lead us to completely new formats of maintenance and related operational risks. New parameters are affecting the propulsion equipment state and new critical issues appear. In Marine Digital we develop a set of hardware and software technologies that provide a set of tools to monitor important vessel's parameters in real-time and to apply modern AI technologies for shipping based on big data generated from vessels and satellites and industrial engineering expertise. Online performance monitoring allows you to transfer the telemetric data to the shore and be notified regarding important events and be able to mitigate the risks in advance. Maintenance prediction algorithms analyze the historical data and online data predicting the future issues within days and weeks providing you the option to be prepared and perform necessary actions in advance.

TOP 5 factors contributing to lower fuel costs for Shipping companies

Get a presentation with a full description of the features and free pilot project with trial of Marine Digital FOS for 2 months

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy"

Get an overview "The Pathway to Zero Carbon Shipping:

IMO Compliance and CII Optimization through SEEMP" on email and download it for FREE! Leave your email now!

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy, as well as consent to subscribe to the newsletter. "

Аdvantage of Fuel Optimization System from Marine Digital:

Marine Digital FOS can be integrated with other system and third-party's solutions through the API. To implement vessel performance monitoring for any vessel, we are using mathematical algorithms, machine learning and the same equipment as in FOS. The more data we collect from vessels, the more precise reports and recommendations our system will perform according to your individual requirements in fleet management.

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

Increased business process speed

Reducing to zero the number of errors

Best offer to the clients

Reduction in operating expenses

Have a questions?