How robotics is changing the maritime industry and what kind of robots are being used in shipping?

Modern robotics is spreading across almost all sectors, including the maritime industry. A huge number of online services, devices, software and, of course, robots have become the drivers of economic and social development.

The digital revolution has brought great changes to our lives: a huge number of online services, devices, software and, of course, robots have become the drivers of economic and social development. Modern robotics is spreading across almost all sectors, including the maritime industry. In this review, we highlight the main use cases and trends of robotics in shipping.

Robotics in the marine industry

The key direction of using robots is the execution of situations that are dangerous or potentially hazardous to human health. For example, the US Maritime Administration or MARAD has partnered with SEA-KIT to build robotic vessels for oil refining. The work is incredibly dangerous for workers who are regularly exposed to chemicals, toxic fumes and have a constantly high risk of fire or explosion.

Maintenance prediction of ships is another major issue. Maintaining a vessel's performance takes a lot of resources from fuel and oil maintenance to regular cleanings. A large number of parts and equipment also need to be serviced or replaced to keep the ship in good condition. It is important to monitor the performance of all units of the vessel, whether it is robotic or not.

Maintenance prediction of ships is another major issue. Maintaining a vessel's performance takes a lot of resources from fuel and oil maintenance to regular cleanings. A large number of parts and equipment also need to be serviced or replaced to keep the ship in good condition. It is important to monitor the performance of all units of the vessel, whether it is robotic or not.

Robots are used for many purposes in the maritime industry, from cleaning and maintenance to fully autonomous vessels with no pilot, no captain and no crew on board. SEA-KIT's Maxlimer is a great example of a fully robotic ship. He can travel autonomously, accompanied by several small drone boats and submarines, which he can send to carry out various tasks. Maxlimer shows just how great the potential for robotic technology is in shipping, and many maritime organizations are starting to take notice.

Source: sea-kit.com

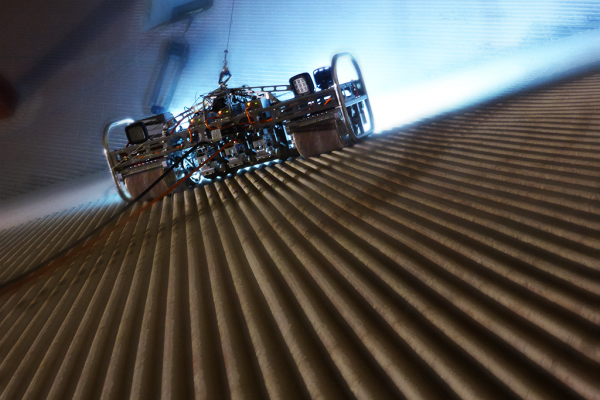

Robots for cleaning and maintaining the ship's hull

It is also a task that can be dangerous, challenging, and tedious. Traditionally, divers perform their work while the ship is moored in port or docked. The HullBUG is an example of an underwater hull cleaning robot. This 30-40 kilogram robot attaches to the bottom of the boat for surface cleaning and creates a negative pressure vortex and moves across the boat's surface using a combination of rotating brushes and water jets to clean the build-up.

Thus, it is possible to carry out preventive cleaning to maintain the working capacity of ships without long-term work hazardous to humans.

Thus, it is possible to carry out preventive cleaning to maintain the working capacity of ships without long-term work hazardous to humans.

The problem of fouling of the ship's hull was also discussed by us earlier. A brief conclusion: The overgrown hull has a key effect on fuel consumption, and therefore on the amount of harmful emissions. Timely cleaning of the body can reduce fuel costs by up to 12%!

Source: searobotics.com

Robots ship inspectors

MINOAS - Robotic Assisted Marine Inspection System - and INCAAS - Inspection Capabilities to Improve Ship Safety - are two European projects of a similar nature. Bluefin Robotics is working on a HUAV underwater robot for the US Navy. SmartBot is also working on a ROBOSHIP robot that can inspect ballast tanks and perform maintenance underwater.

Huge ships such as Panamax or larger are difficult to test due to the surface area of the ship, materials and paint used. Finding cracks, corrosion, and other serious complications can be difficult, especially underwater, where it is dark and cloudy. This means that inspectors have to spend a lot of time on every meter of the vessel.

A team of students from ETH Zurich and ZHdK has teamed up with Alstom Inspection Robotics to create a lightweight and versatile ship inspection robot. The prototype ship inspector robot, or SIR, has four magnetic wheels with an overlapping wheelbase, allowing it to move around the bottom of the ship, even around I-beams and other obstacles. SIR is not the only robot being developed for this purpose.

A team of students from ETH Zurich and ZHdK has teamed up with Alstom Inspection Robotics to create a lightweight and versatile ship inspection robot. The prototype ship inspector robot, or SIR, has four magnetic wheels with an overlapping wheelbase, allowing it to move around the bottom of the ship, even around I-beams and other obstacles. SIR is not the only robot being developed for this purpose.

Source: inspection-robotics.com

Fire robots on ships

In the event of a fire on a ship, these robots are capable of performing tasks such as turning valves, collecting and dragging fire hoses, searching for survivors, and can withstand temperatures up to 500 degrees Celsius. It also features multimodal sensor technology for advanced navigation, allowing it to overcome obstacles and stay upright, even when the sea is rolling and tilting. Robots can respond to gestures and commands, and its sensor package includes a camera and gas sensor. An infrared and UV camera helps him see through smoke and detect the source of excess heat, respectively.

The SAFFiR Firefighter Robot, developed by the Naval Research Laboratory in collaboration with the Virginia Institute of Technology and other US universities, is an autonomous humanoid robot capable of detecting and extinguishing fires aboard a ship and working side by side with human firefighters using advanced technology.

Source: cdn10.bostonmagazine.com

Anti-piracy robots

The Recon Scout Throwbot from ReconRobotics is a small dumbbell-shaped robot that can penetrate the main deck of a boat for discreet inspections. Magnetic wheels allow it to crawl to the side of the ship on deck and maneuver. Cameras allow operators to see what's happening in real time, even at night, thanks to infrared sensors. All of this is controlled by a joystick-based remote control. These developments are used by the US Navy.

Robotization in the maritime industry can help accomplish a number of important tasks with greater efficiency and safety, provided they do not affect employment opportunities in an industry that is already bleak in several parts of the world. Advanced robotics is already impacting maritime operations from the environmental benefits provided by regular hull cleaning to safer waters achieved through anti-piracy measures, the applications are extensive. It just goes to show that robots are really changing the marine sector. A healthy balance between robotization and seafarers' efforts is key to improving the quality and safety of ship operations for the benefit of the maritime industry.

Read also: Sensors and IoT in the shipping industry

Robotization in the maritime industry can help accomplish a number of important tasks with greater efficiency and safety, provided they do not affect employment opportunities in an industry that is already bleak in several parts of the world. Advanced robotics is already impacting maritime operations from the environmental benefits provided by regular hull cleaning to safer waters achieved through anti-piracy measures, the applications are extensive. It just goes to show that robots are really changing the marine sector. A healthy balance between robotization and seafarers' efforts is key to improving the quality and safety of ship operations for the benefit of the maritime industry.

Read also: Sensors and IoT in the shipping industry

We also wrote about the evolution of sea piracy, where we considered in detail the possible options for protecting and countering piracy, but robots were not included in that review, so we will tell you about how robots help in the fight against piracy.

Source: reconrobotics.com

TOP 5 factors contributing to lower fuel costs for Shipping companies

Get a presentation with a full description of the features and free pilot project with trial of Marine Digital FOS for 2 months

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy"

Get an overview "The Pathway to Zero Carbon Shipping:

IMO Compliance and CII Optimization through SEEMP" on email and download it for FREE! Leave your email now!

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy, as well as consent to subscribe to the newsletter. "

Аdvantage of Fuel Optimization System from Marine Digital:

Marine Digital FOS can be integrated with other system and third-party's solutions through the API. To implement vessel performance monitoring for any vessel, we are using mathematical algorithms, machine learning and the same equipment as in FOS. The more data we collect from vessels, the more precise reports and recommendations our system will perform according to your individual requirements in fleet management.

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

Increased business process speed

Reducing to zero the number of errors

Best offer to the clients

Reduction in operating expenses

Have a questions?