Why do shipping companies need vessel antifouling coatings and how much fuel they lose if the hull is in bad condition?

The application of a special coating and regular repair of the hull to combat clogging of the underwater part of the ship with algae and shells is costly. However, due to the poor quality of anti-fouling coatings, the shipping company may lose significantly more

All the time shipping faced the problem of fouling the underwater part of the ship with algae, seashells and other marine life. The ocean is a real living organism, especially well growing algae and coral in the tropical zone. Ships that walk in the Indian Ocean are most susceptible to hull fouling.

Previously, ships cleaned from organic seams by hand, with the help of special scrapers. Otherwise, the vessel could quickly rot and let flow.

Previously, ships cleaned from organic seams by hand, with the help of special scrapers. Otherwise, the vessel could quickly rot and let flow.

How do ships hull protect today?

The modern paint industry has come up with special anti-fouling coatings. These coatings exist of different types, designed for different hulls, depending on the tasks and type of vessel, from the area of navigation, etc.

Today there are several types of paint that do not give living organisms to develop on it. Typically, the composition of such paint includes copper particles. Back in the time of sailing shipbuilding, the bottoms of the ships were sheathing with copper sheets to slow down the rot of the tree.

There are also paints with zinc content or ECONEA as a biocide - it disrupts photosynthesis in algae, which reduces the amount of mucus and weeds on the bottom of the ship.

But any paint wears off sooner or later due to friction against the water. Therefore it is necessary to repair the ship and to paint it again every three to five years. If you tighten with repair, then any modern vessel will be covered in a layer of living plants, and getting rid of them will be more difficult. In reality, the losses are quite serious due to losses in the energy efficiency of the vessel. The vessel's hull becomes rough, its streamness falls.

There are also paints with zinc content or ECONEA as a biocide - it disrupts photosynthesis in algae, which reduces the amount of mucus and weeds on the bottom of the ship.

But any paint wears off sooner or later due to friction against the water. Therefore it is necessary to repair the ship and to paint it again every three to five years. If you tighten with repair, then any modern vessel will be covered in a layer of living plants, and getting rid of them will be more difficult. In reality, the losses are quite serious due to losses in the energy efficiency of the vessel. The vessel's hull becomes rough, its streamness falls.

How much do the shipping companies lose on the low-quality of the vessel's antifouling coatings?

Company Hilon carried out a long - standing research that proved: The use of anti - fouling coatings for 60 months did away with reduced loss of stroke, approximately, by 4%. Taking into account that compensating for a percentage reduction in the speed of travel requires a 3% increase in fuel consumption, the total fuel economy was more than 10% - a saving of more than $150,000 per year fuel.

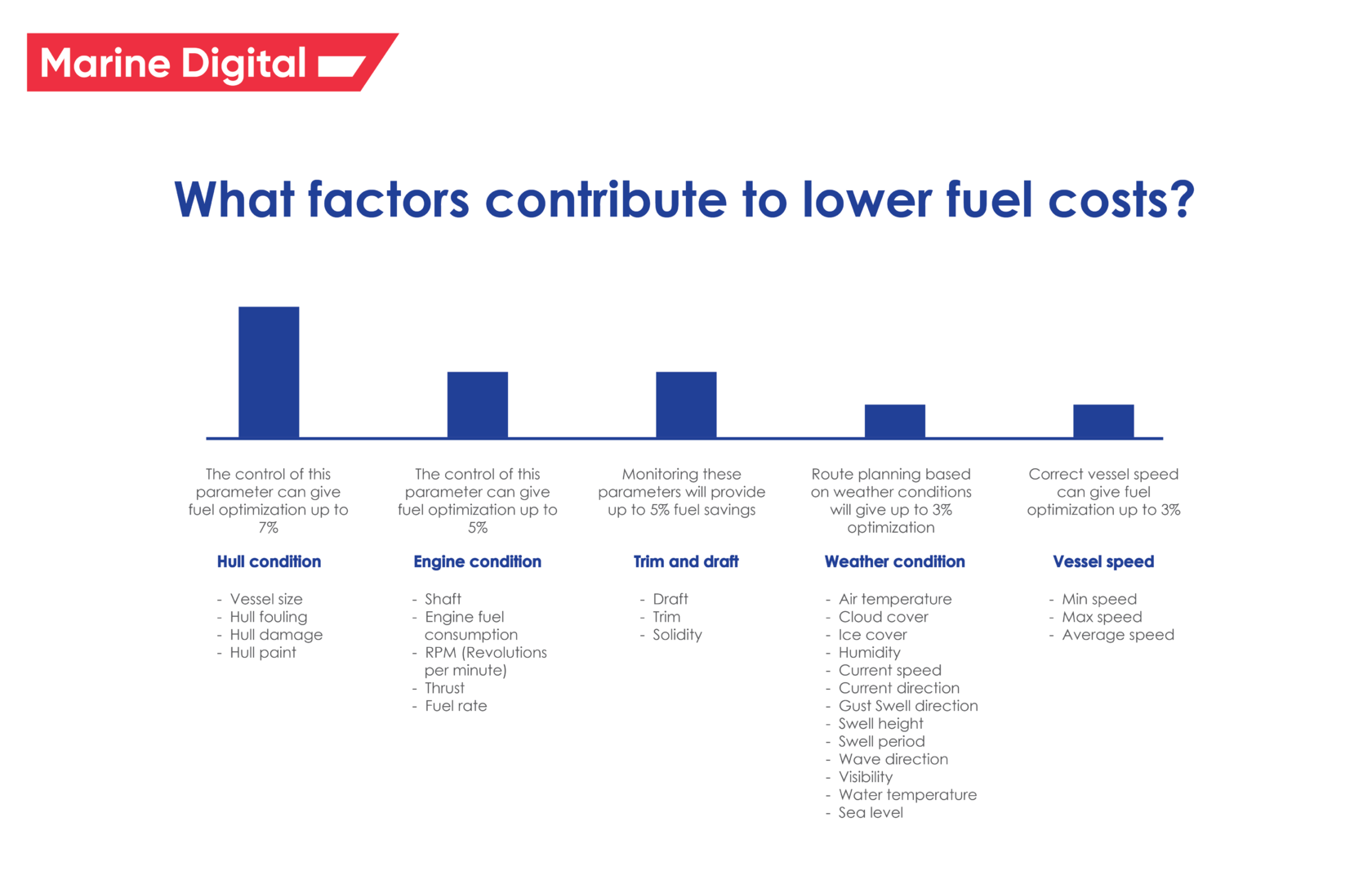

These indicators are also confirmed by Marine Digital. The fouling of the ship's Hull is one of the key parameters affecting fuel consumption (from 7% to 12%).

These indicators are also confirmed by Marine Digital. The fouling of the ship's Hull is one of the key parameters affecting fuel consumption (from 7% to 12%).

Vessel performance monitoring and fuel optimization system (FOS) being developed at Marine Digital collects data from the ship on 5 key parameters affecting fuel consumption (Hull condition, Engine, Trim and Draft, Wheather condition, Vessel Speed) processes data through a machine learning network and provides recommendations for managers of a shipping company in Cloud based interface. Such recommendations may be, for example, building an optimal route due to weather conditions or notifying the need to clean the hull.

Moreover, Marine Digital FOS is able to quickly track the quality of the last cleaning or painting of the ship, thus the fleet managers will be able to decide to send the ship to warranty service or change contractors.

Moreover, Marine Digital FOS is able to quickly track the quality of the last cleaning or painting of the ship, thus the fleet managers will be able to decide to send the ship to warranty service or change contractors.

TOP 5 factors contributing to lower fuel costs for Shipping companies

Get a presentation with a full description of the features and free pilot project with trial of Marine Digital FOS for 2 months

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy"

Get an overview "The Pathway to Zero Carbon Shipping:

IMO Compliance and CII Optimization through SEEMP" on email and download it for FREE! Leave your email now!

"Clicking the button, you consent to the processing of personal data and agree to the privacy policy, as well as consent to subscribe to the newsletter. "

Аdvantage of Fuel Optimization System from Marine Digital:

Marine Digital FOS can be integrated with other system and third-party's solutions through the API. To implement vessel performance monitoring for any vessel, we are using mathematical algorithms, machine learning and the same equipment as in FOS. The more data we collect from vessels, the more precise reports and recommendations our system will perform according to your individual requirements in fleet management.

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

If you have any questions about the solutions and the Marine Digital System platform, write to us, we will be happy to answer

Increased business process speed

Reducing to zero the number of errors

Best offer to the clients

Reduction in operating expenses

Have a questions?